Beverage

The issue:

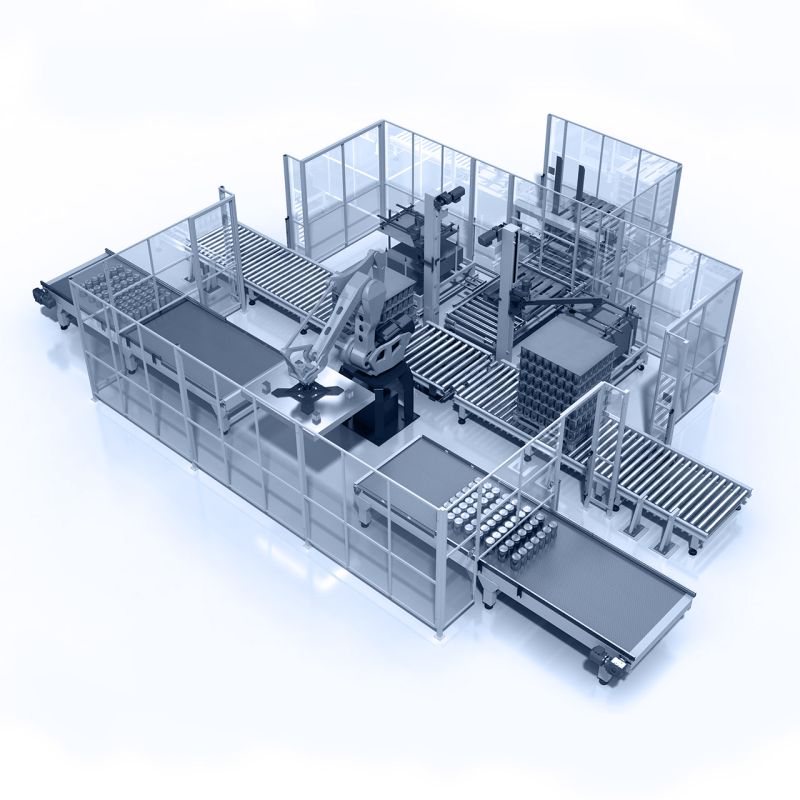

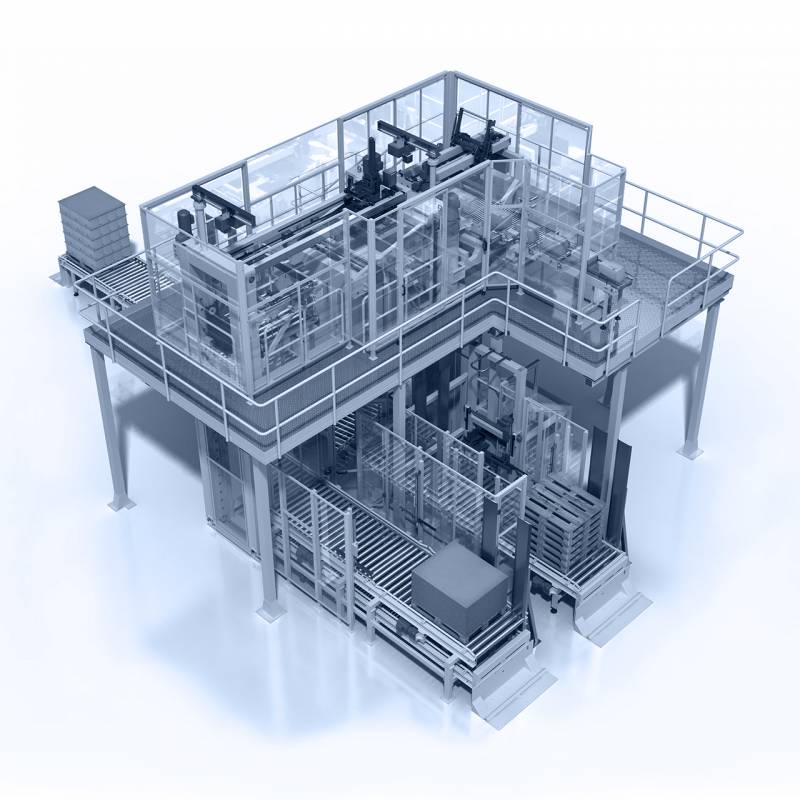

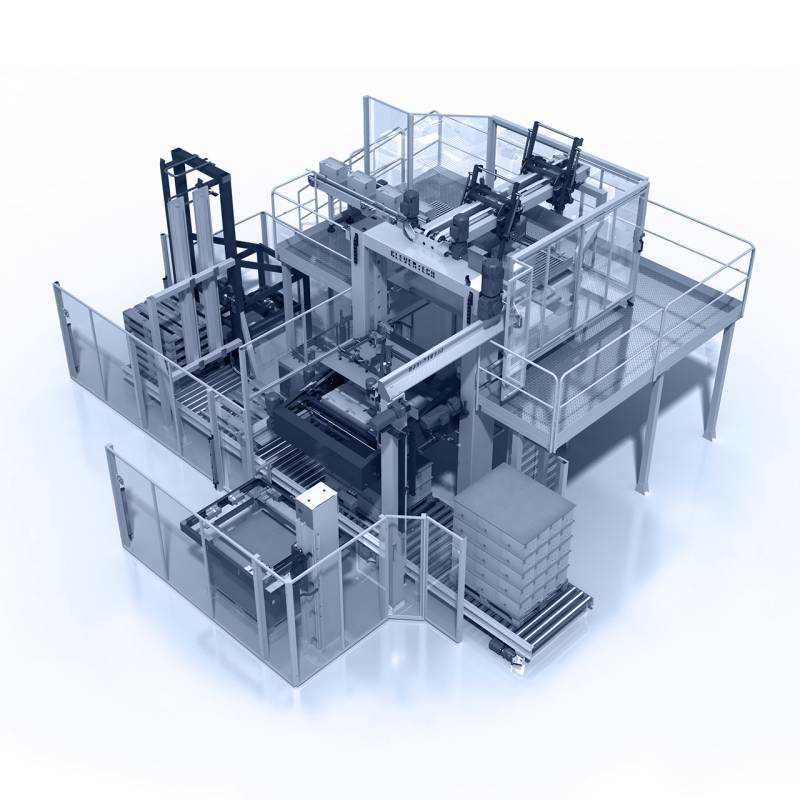

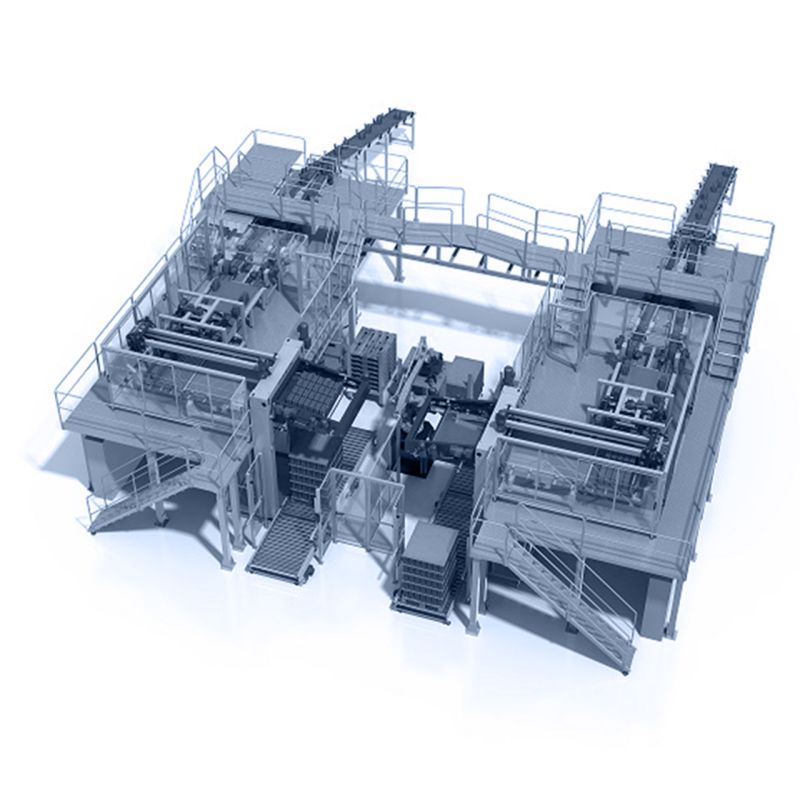

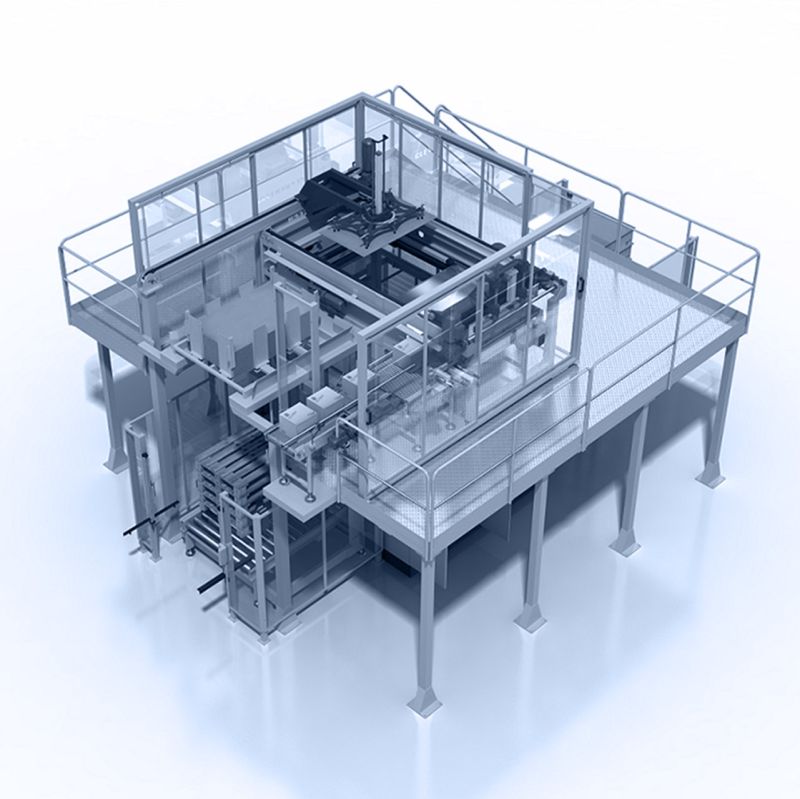

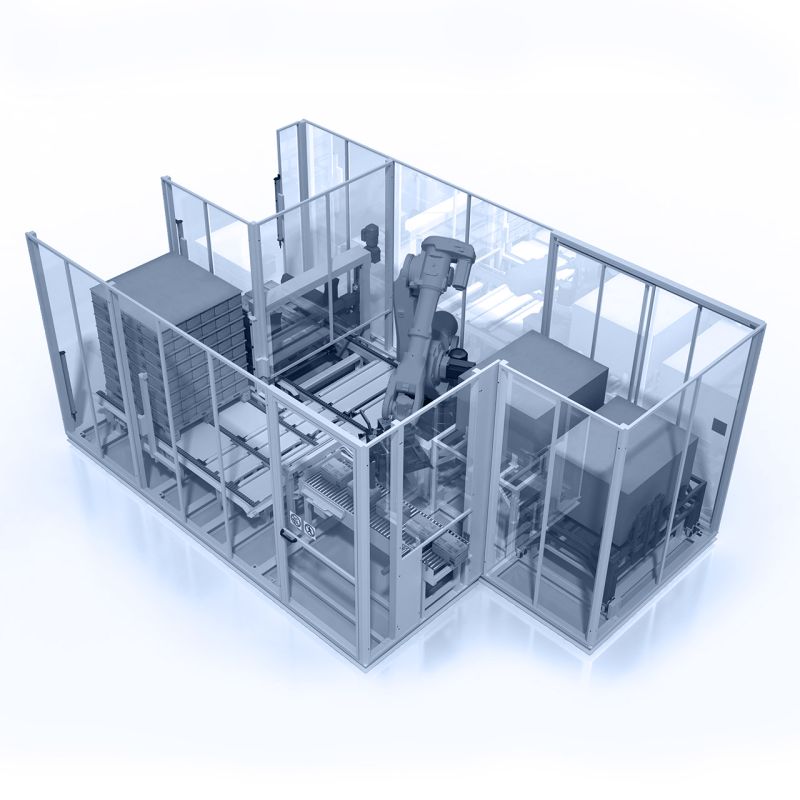

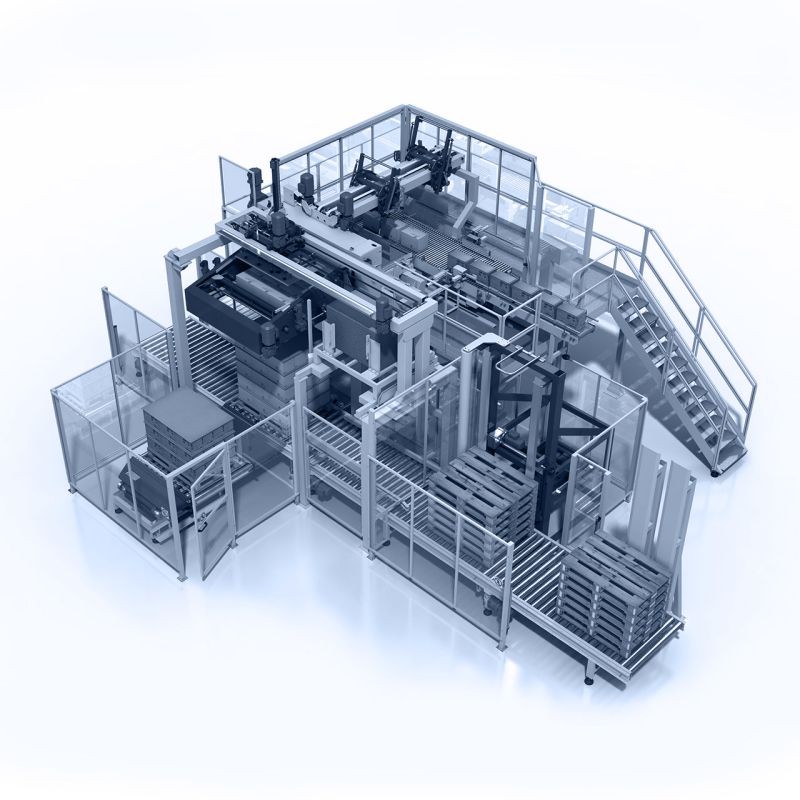

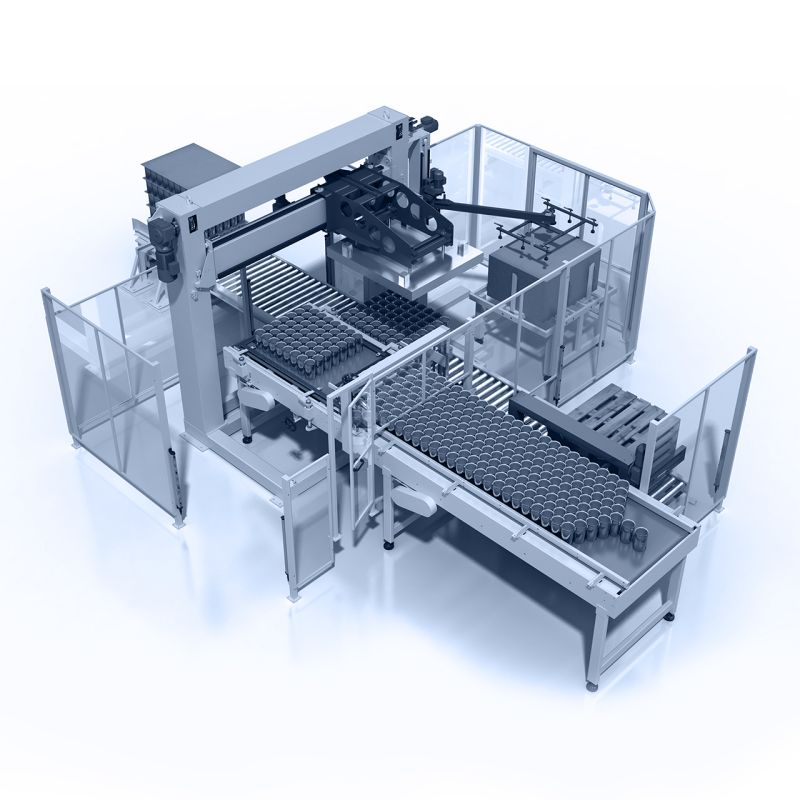

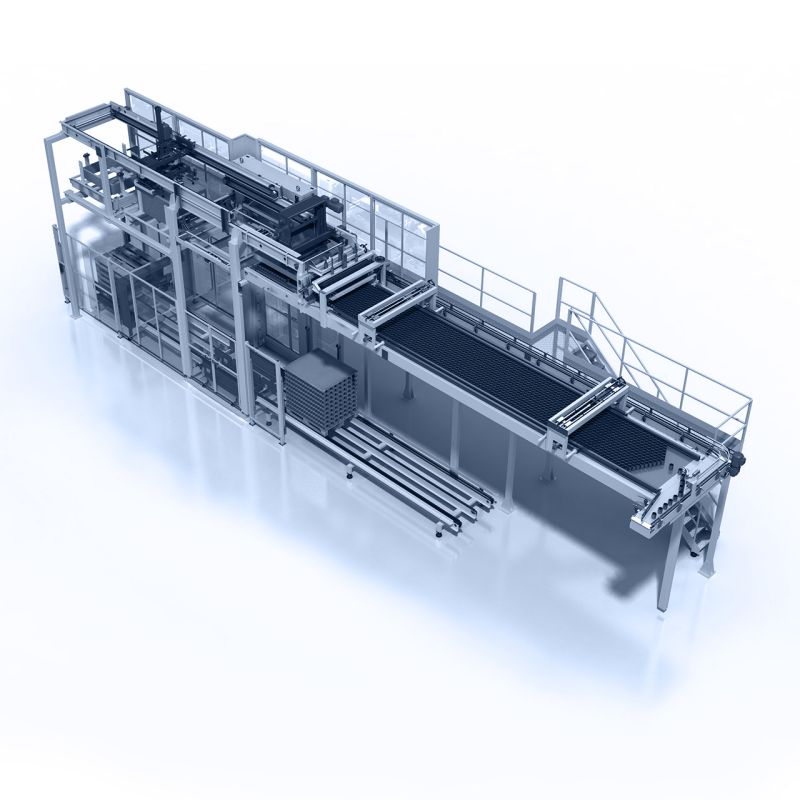

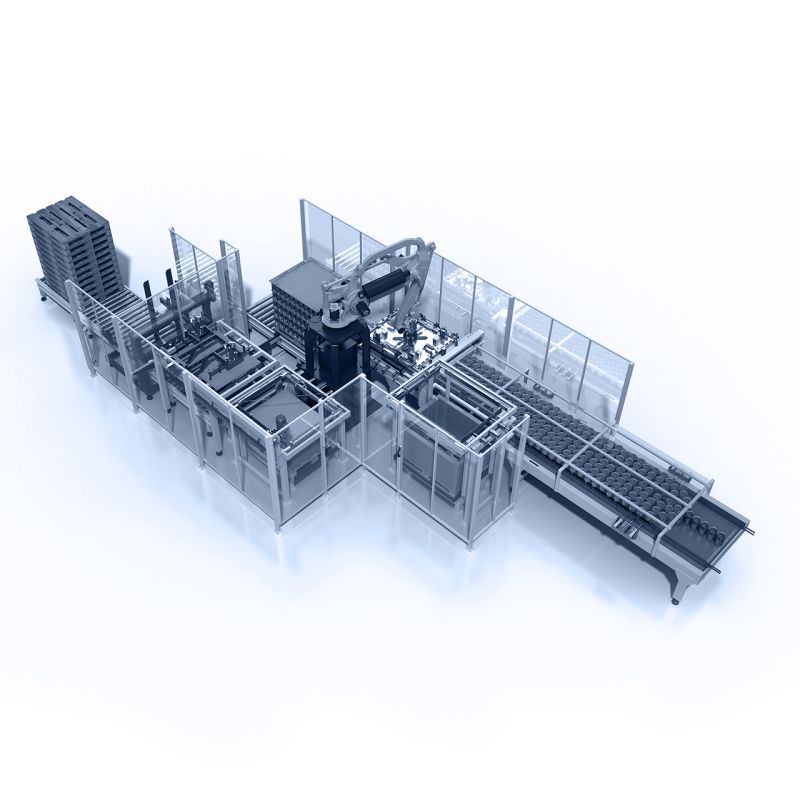

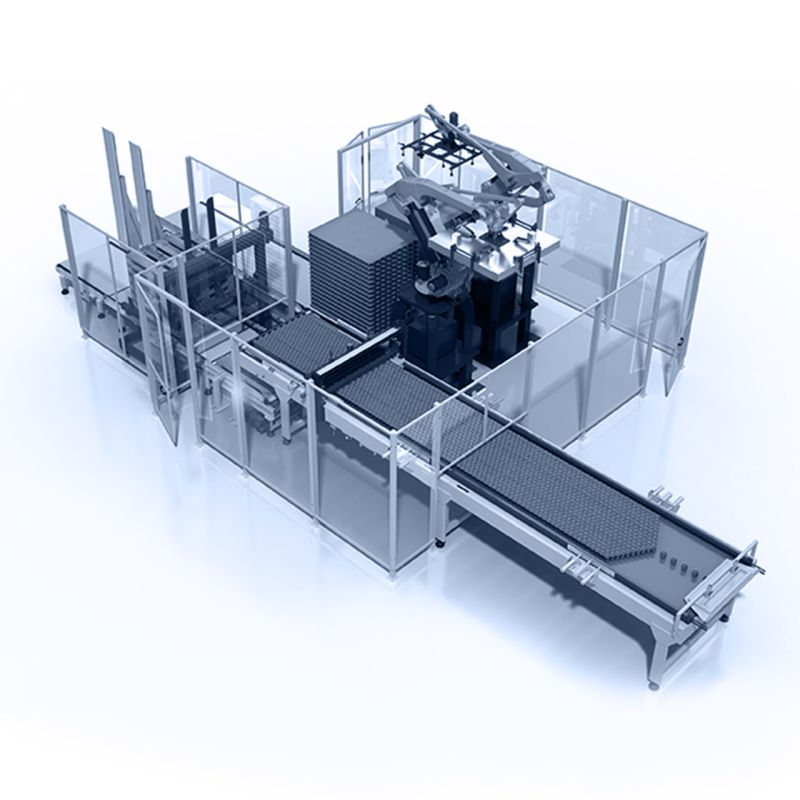

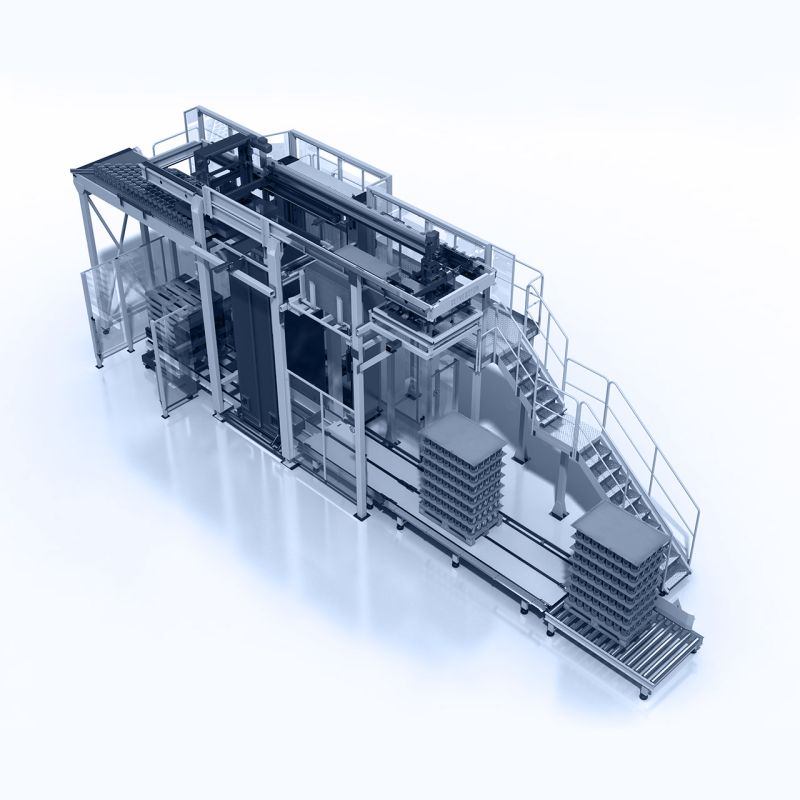

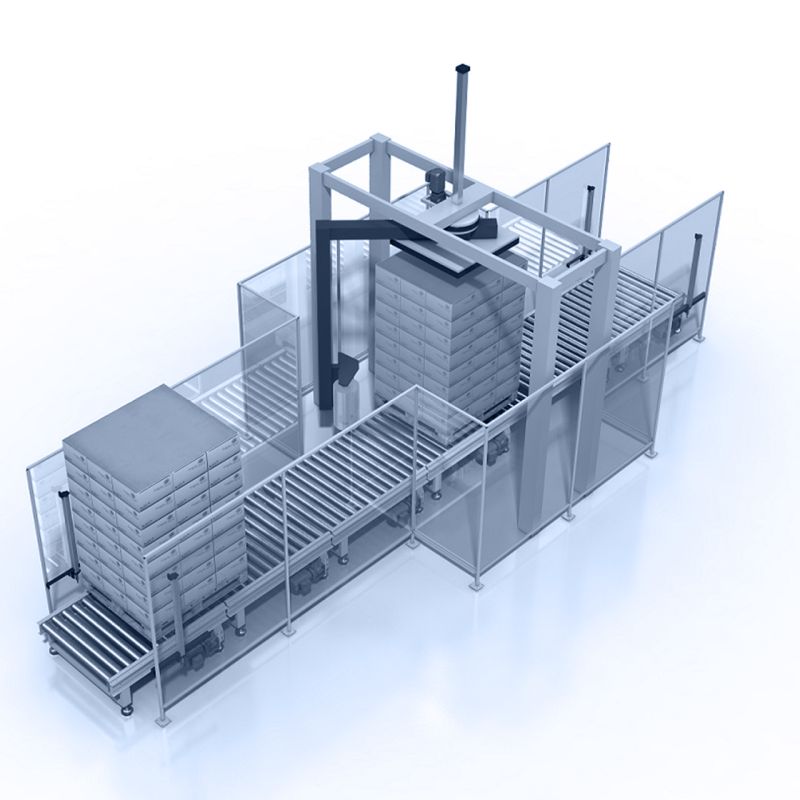

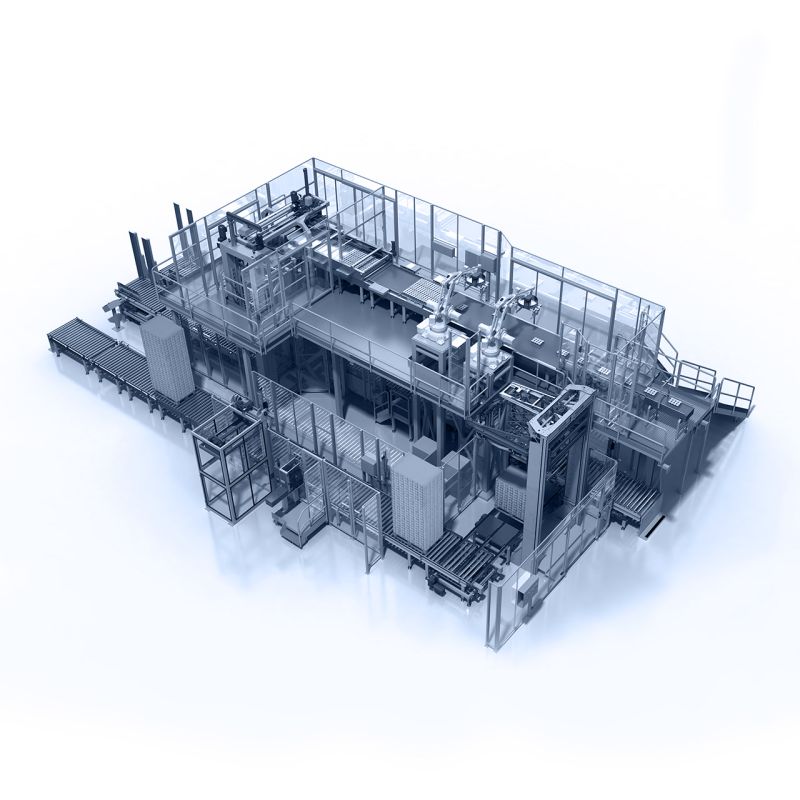

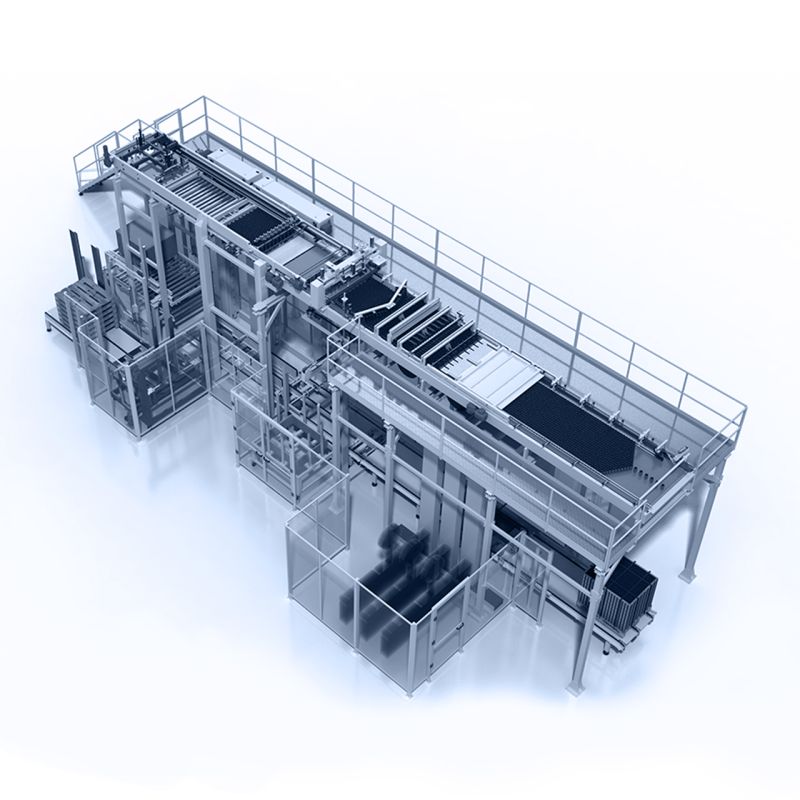

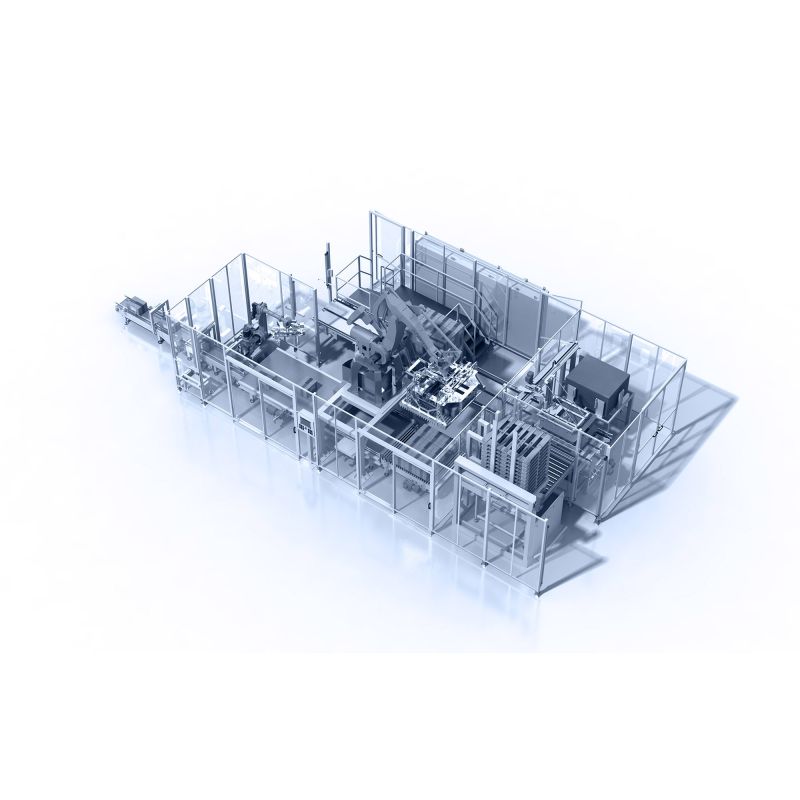

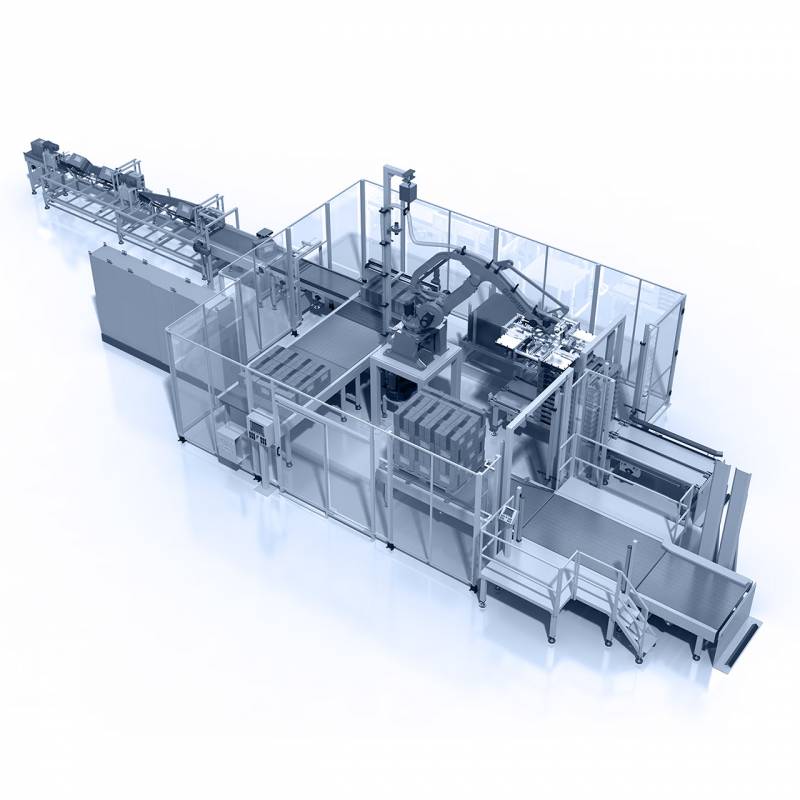

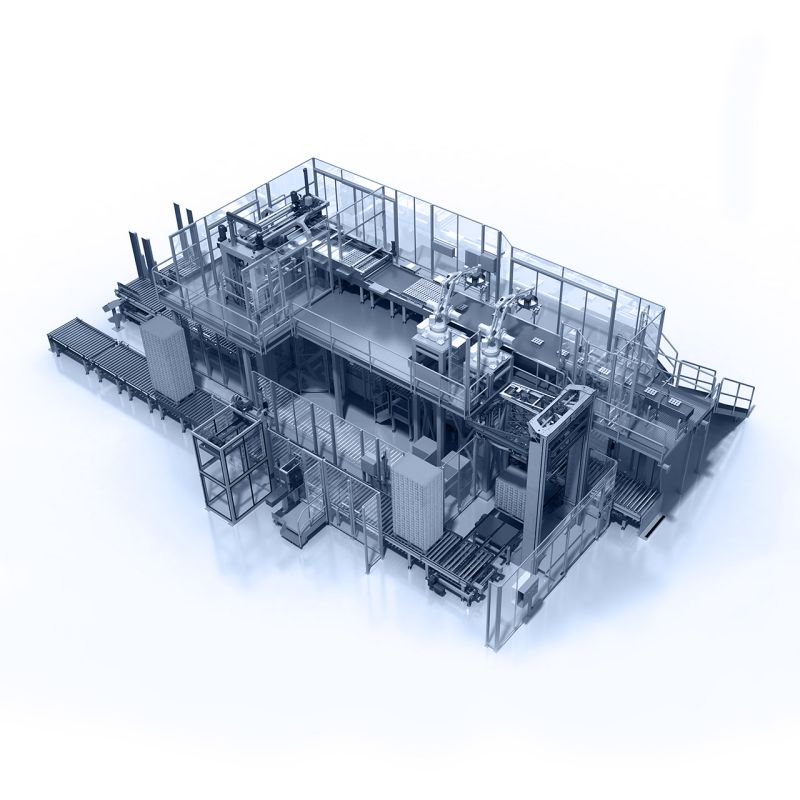

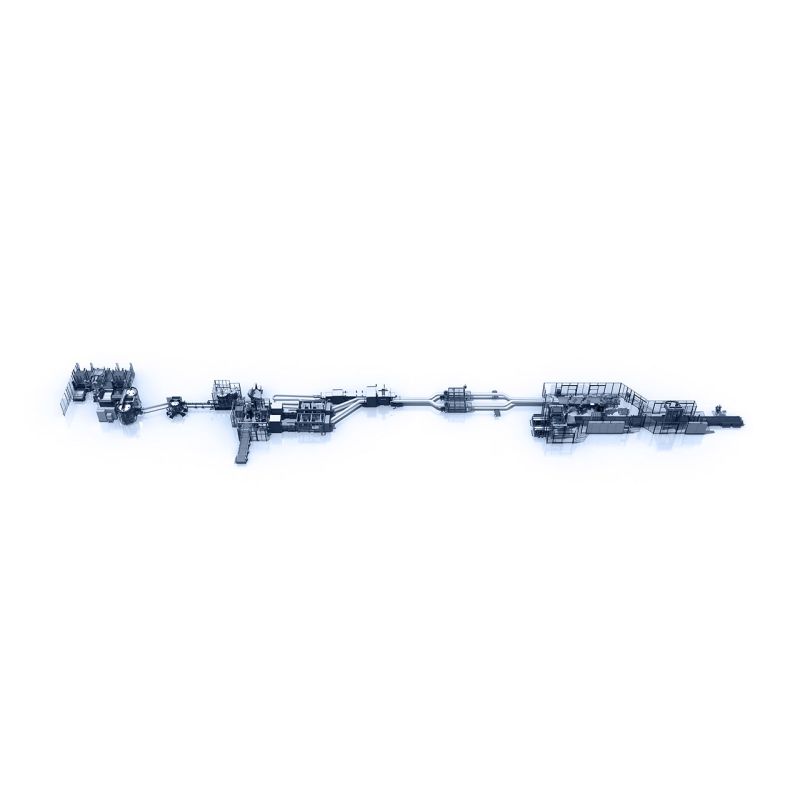

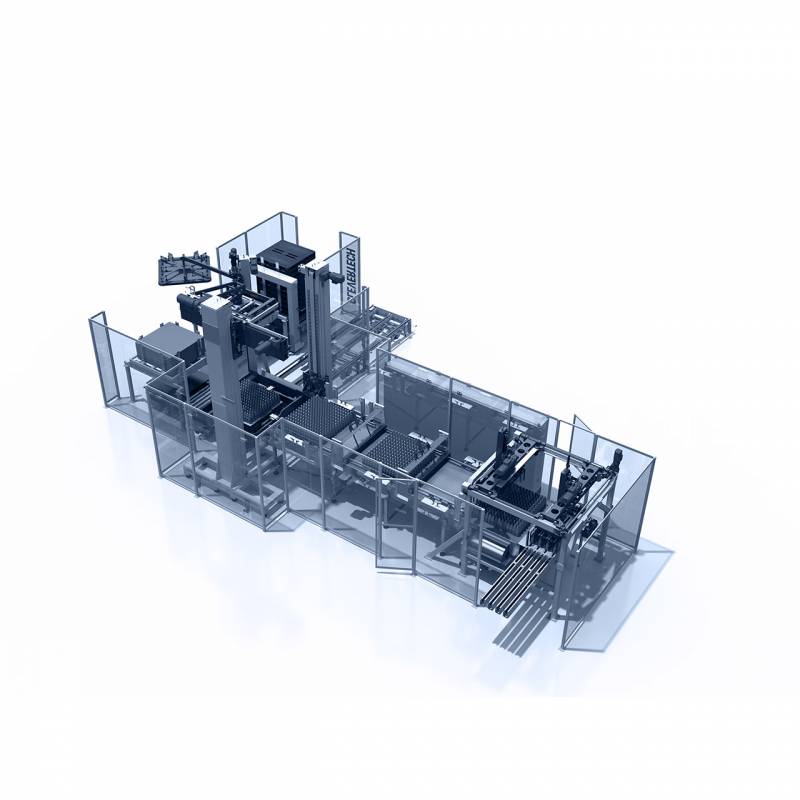

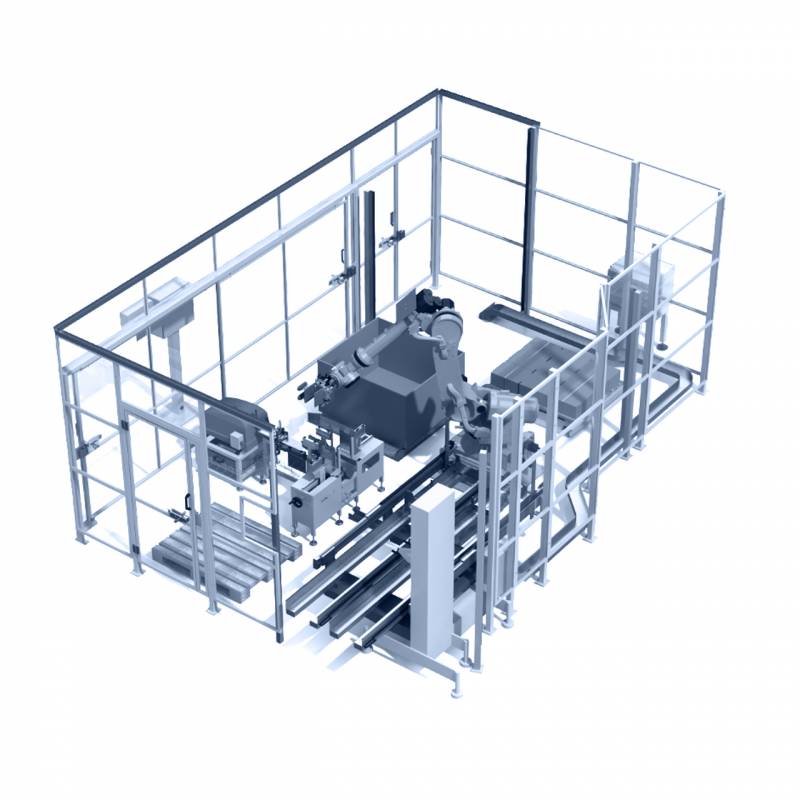

to create a high-speed bulk palletizing system for empty aluminium bottles, as well as a super sorting system composed of a depalletising system, inspection line and palletiser for empty bottles. Specifically, the challenge was reaching the required speed of almost 1800 bottles per minute as well as the highly unstable product in question. It was also necessary to create a system which is able to create complete layers of products without voids, and so a void reduction system was implemented. The customer also required the layer pads and empty pallets to be loaded from the ground, in order to facilitate the work of the forklift operators.

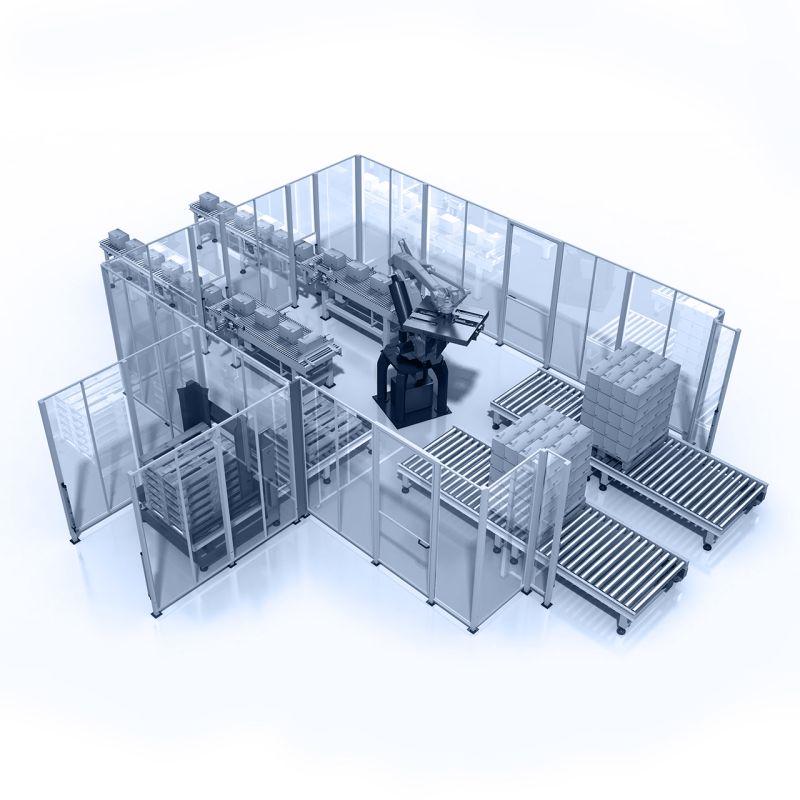

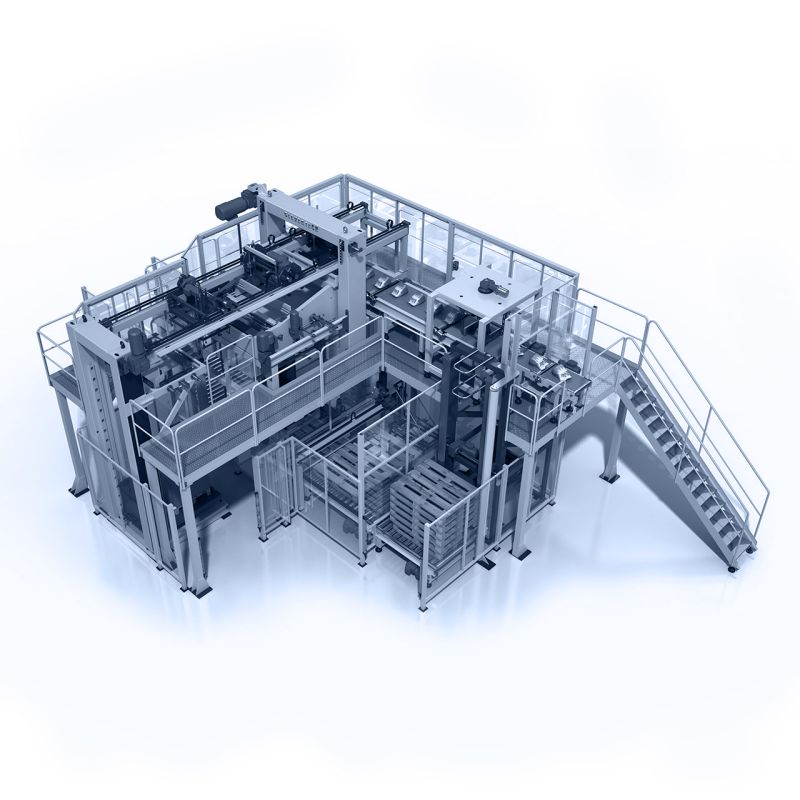

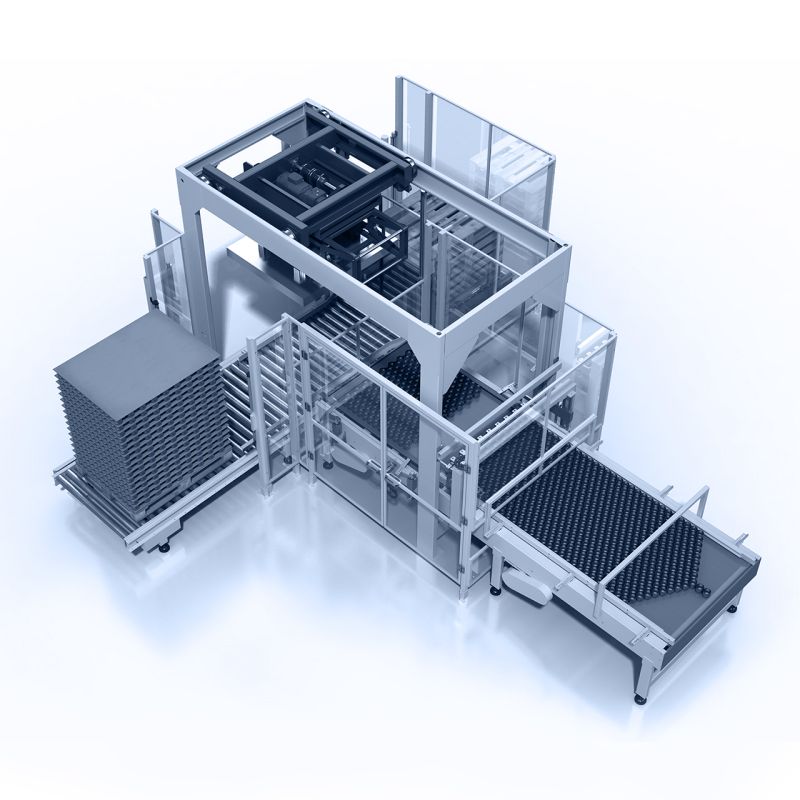

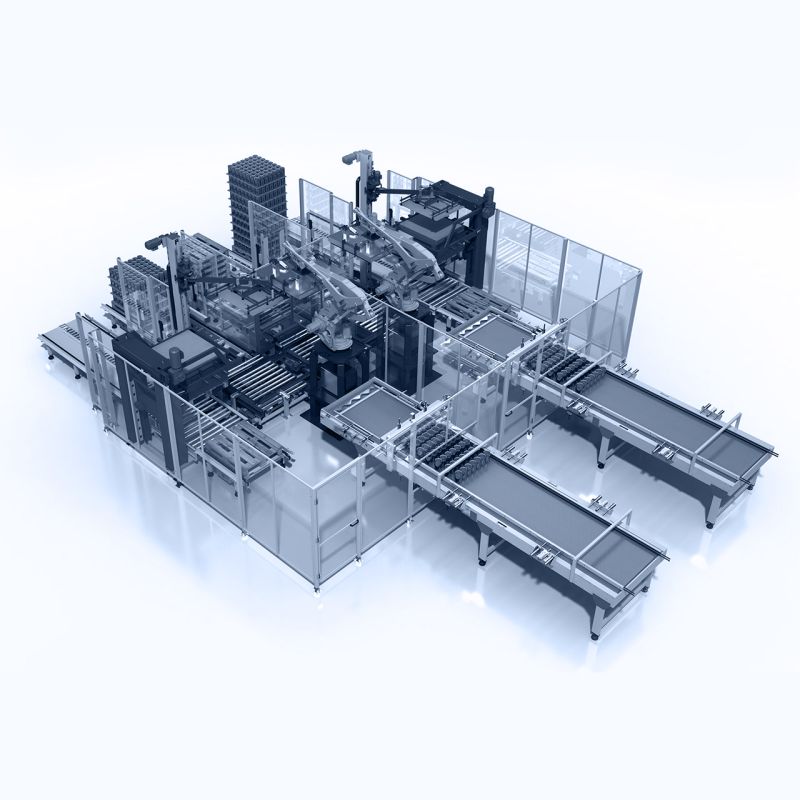

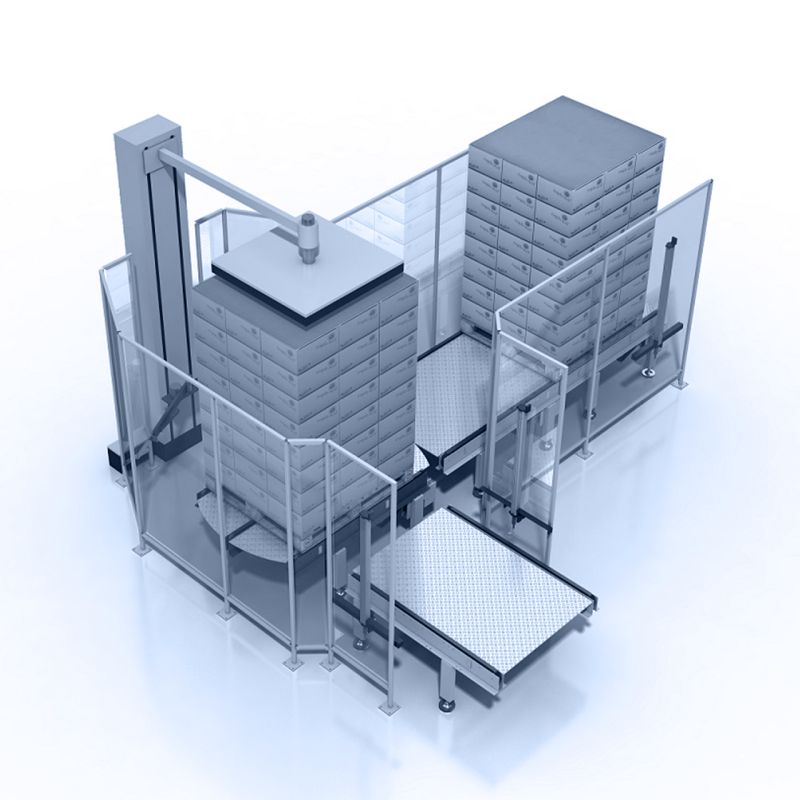

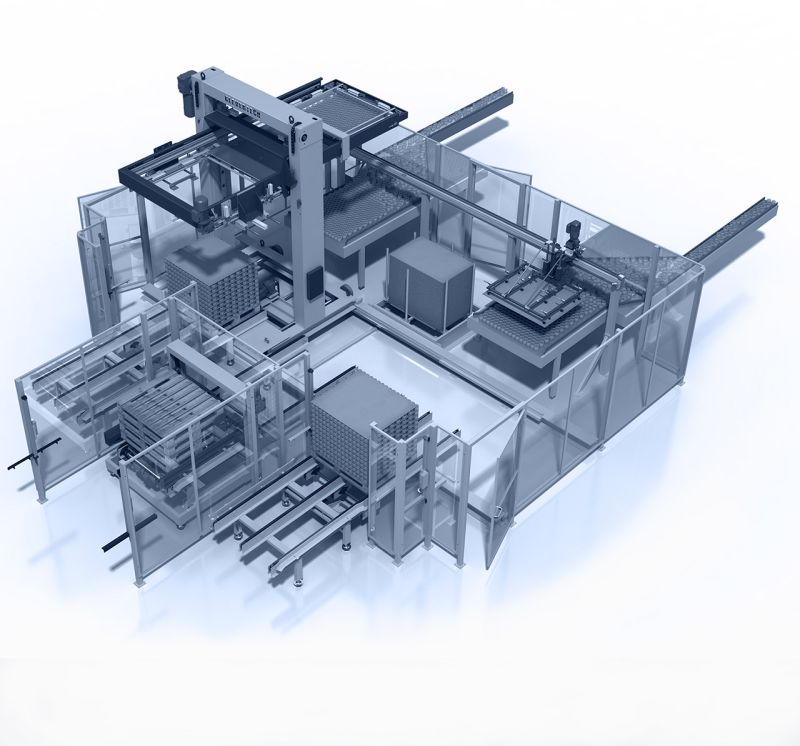

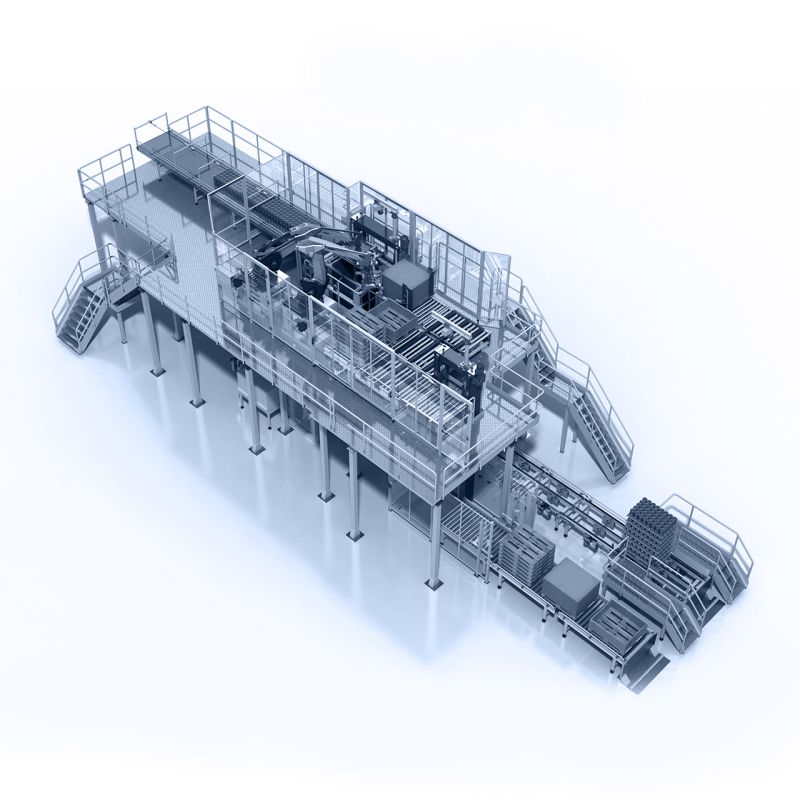

The system developed by Clevertech:

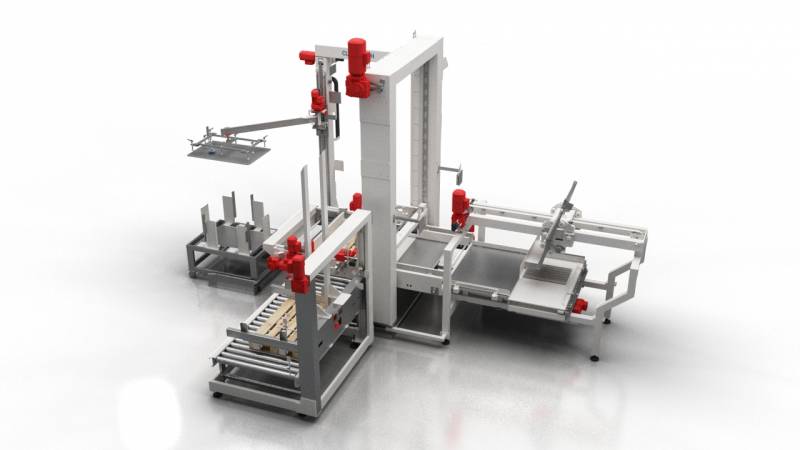

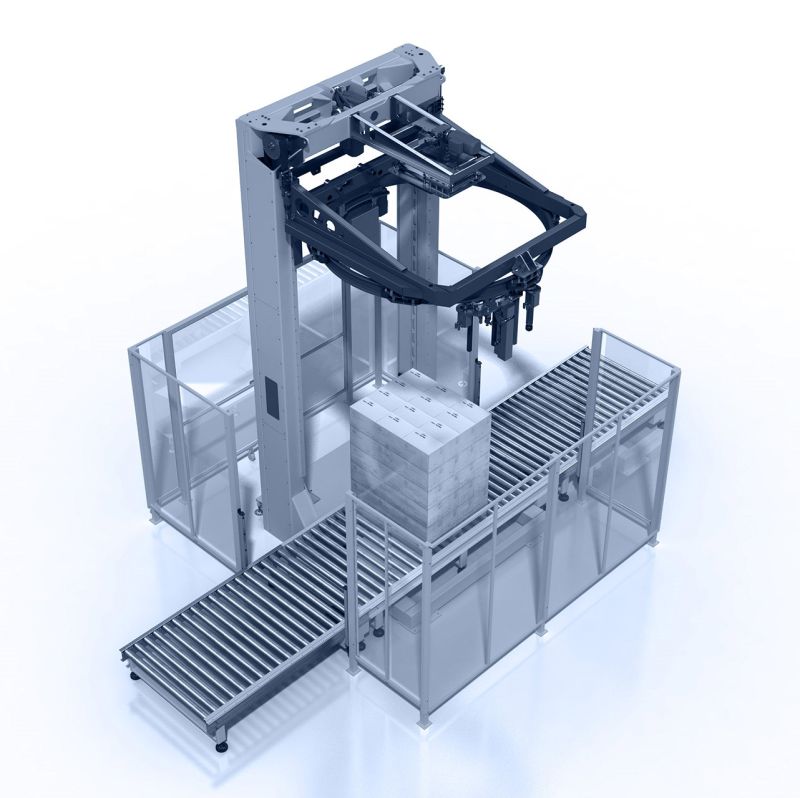

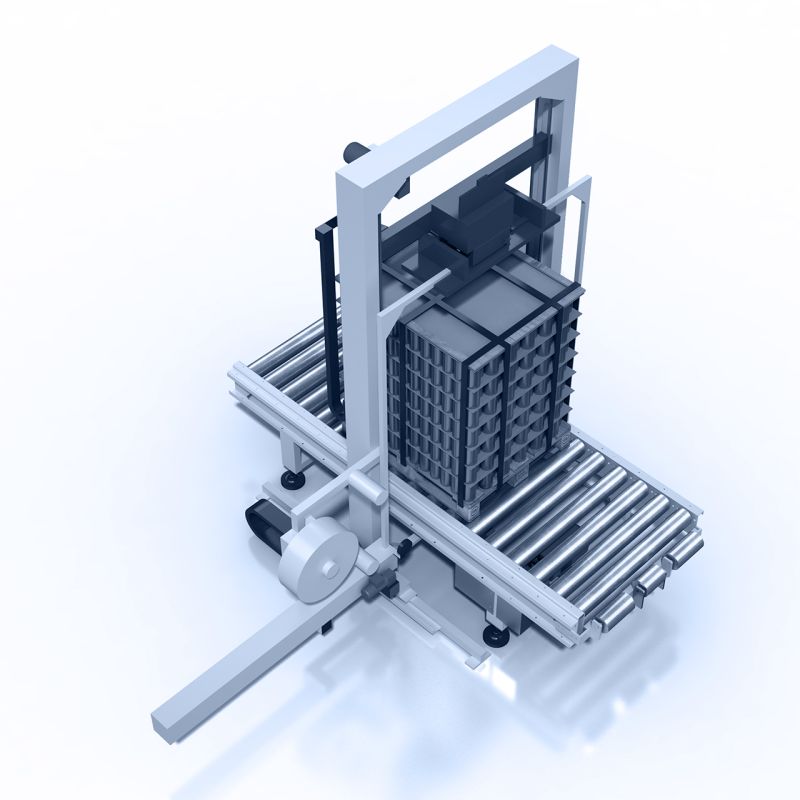

the model AP EC 50 MCF DBS 1 FAST TRANSFER palletising system for empty cans. This is a high-speed bulk palletiser, equipped with the innovative CTH MCF (Mass Channel formation) system, which provides monitoring of the bulk product in order to reduce the presence of voids during the layer formation. This was made possible by a system of sensors positioned on each channel. The dedicated sensor monitors the presence of bottles in the channels and adjusts the layer forming speed via the specific software. The transfer of the layer is performed with a servo-motorised pushing system, combined with an additional, independent front pushing device which prevents the overturning of the first row of bottles during the initial transfer phases. (positive control). The layer pad management system allows a complete pallet of layer pads to be loaded at ground level. Once the pallet is empty, it can be changed automatically without stopping the machine's operation.

Performance data: 1800 bottles/min. 30 pallets/hour. Efficiency: over 99%.

INFORMATION REQUEST

FOR THE PRODUCT

Beverage

MORE PRODUCTS